Our process is inovative and effetive

The Rise Guys lifting process starts with a thorough inspection to evaluate the condition of your concrete and identify the underlying causes of sinking or cracking. This allows us to develop a targeted plan for effective results.

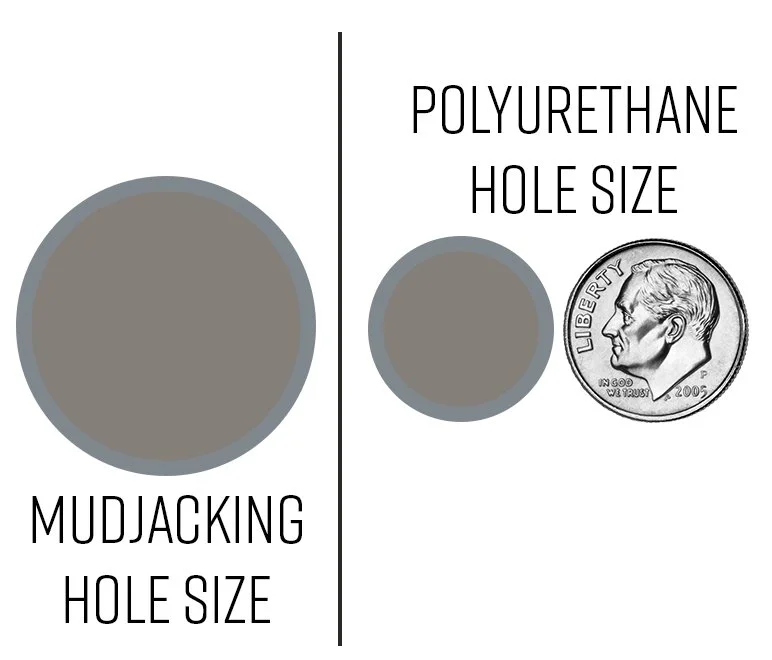

Once the assessment is complete, we begin by drilling small, strategically placed holes—each about the size of a penny. Through these access points, we inject a specialized two-part polyurethane solution. As the components mix, they expand into a durable foam that works on multiple levels: it fills voids beneath the slab, stabilizes the soil, and gently lifts the concrete back to its original—or near-original—position.

After the lift is complete, we carefully patch the injection holes, leaving your surface clean and ready to use. The entire process is fast and minimally invasive. In most cases, projects are completed in a single day, and thanks to the rapid curing time of the foam, your concrete is ready for use almost immediately.

At Rise Guys, we respect your time and your property—providing efficient, high-quality solutions that get you back to normal, fast.

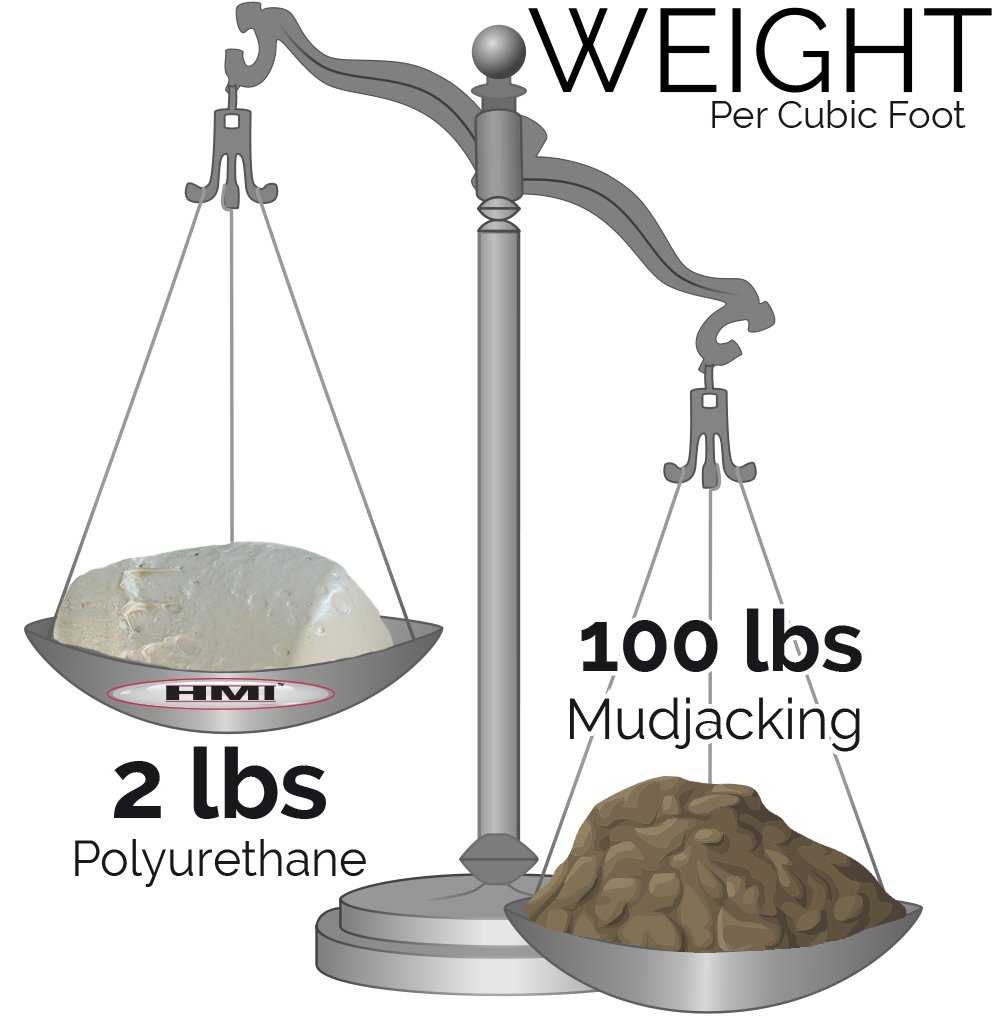

Polyurethane injection is a modern alternative to traditional mudjacking, offering several key advantages. Unlike mudjacking, which uses a heavier slurry of cement and soil, polyurethane foam is lightweight, expands precisely, and cures quickly.

Some drawbacks of mudjacking include:

Erosion Susceptibility: The primary drawback is that the mudjacking slurry can erode or wash away due to water

Heavier material can further stress or sink unstable soils.

Larger injection holes (typically 1–2 inches in diameter) compared to the small, penny-sized holes used with foam.

Longer cure times, which can delay use of the repaired area.